Evolution of the Workshop

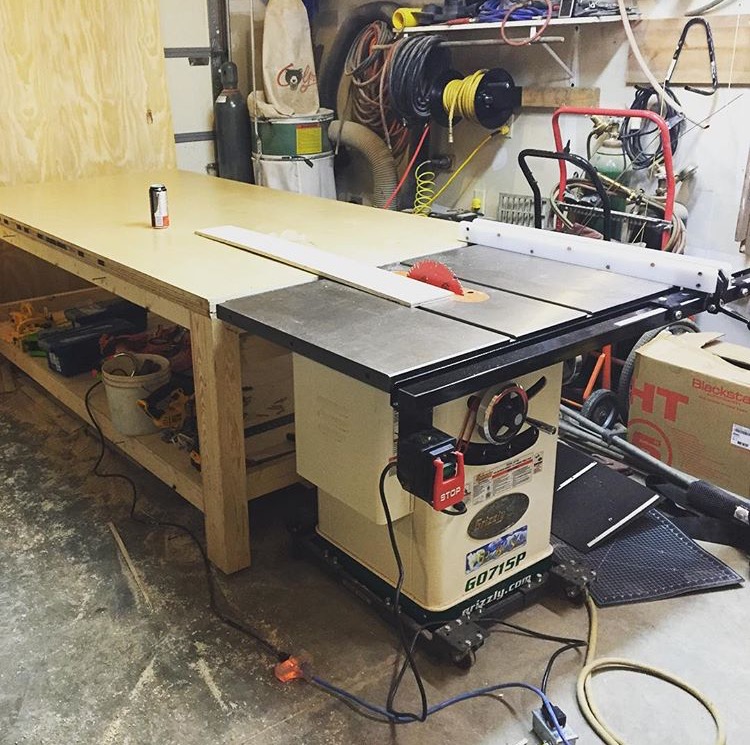

DuckHill started as a hobby shop in the basement of a farmhouse outside of Platteville, Wisconsin which two of my best friends and I were renting. Because I didn’t feel like I had enough going on as an event coordinator, and technical director at the local university, I managed to convince my roommates we should have a flock of chickens, ducks, and geese. It was during construction of the pen, and coop for the birds I realized it was time to own more tools than a 20oz hammer, hand-me-down craftsman circular saw, and my 20 volt-max Dewalt impact driver. So I bought a Grizzly G0715p table saw and started to set up shop in fall of 2015, not knowing that 10 months later I would be packing it up and moving north to River Falls.

Now before you get any ideas about setting up your own shop, I have to stress that the basement of a century-old farmhouse, with low ceilings, is not an ideal space for a workshop, They often leak, if not flood, turning the floor into a series of small rivers eventually becoming a shallow inland sea. The stairs can be set at such an angle that makes it impossible to get a full 4’x8′ sheet of plywood into the shop. The ceilings are typically low because, well, no one expected you to want a workshop down there; so the plumbing pipes are hung right at head bumping level. But ultimately you make due with what you have. There was a bonus though, a previous tenant or owner had installed two workbenches that must have once been from an old bowling alley. It was a nice start and meant there were fewer things I needed to build to get working. I was able to add lumber storage over one workbench, and the other became a miter station.

In the summer of 2016, I was offered a new opportunity at my Alma Mater; within two weeks I had packed everything, including the shop, and moved five hours north to River Falls Wisconsin. Without enough time to figure out a plan for the workshop, all my tools ended up in storage for a few months. Until my parents suggested that I could set up shop in their garage. Now again, this isn’t an ideal situation because we live an hour apart, but it is a million times better than everything rusting in a storage unit. And I’m not hitting my head on any plumbing or ductwork. There were some limitations to overcome; mainly I had to figure out how to economize the space. All of my tools had to fit in one stall of the garage. So I found plans for a mobile miter saw station and designed a giant 4’x8′ multi-use workbench/outfeed table with lots of storage underneath. Then I set to work. From December 22nd-31st working like a madman, I built the second iteration of DuckHill, and still fit in several family Christmas gatherings, and a New Year’s Eve wedding. Over the course of the ensuing year, I have continued to adjust the space to fit my needs and make it more efficient and flexible. More posts will be dedicated to this topic so check back often to see our progress.